BAG & DRUM FILLING

- Fill bulk bags or drums on a weigh scale, many options available.

- Bags from 25 to 60 cubic sq. ft. and drums up to 55 gallon.

- DCL’s Rotary Bagfill Station can fill up to 50 bags an hour.

BAG & DRUM FILLING

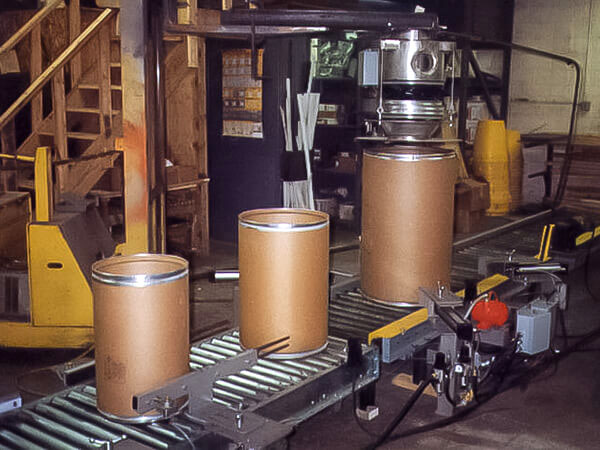

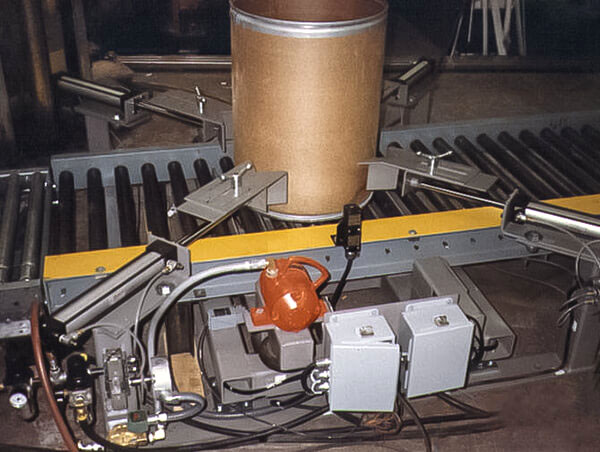

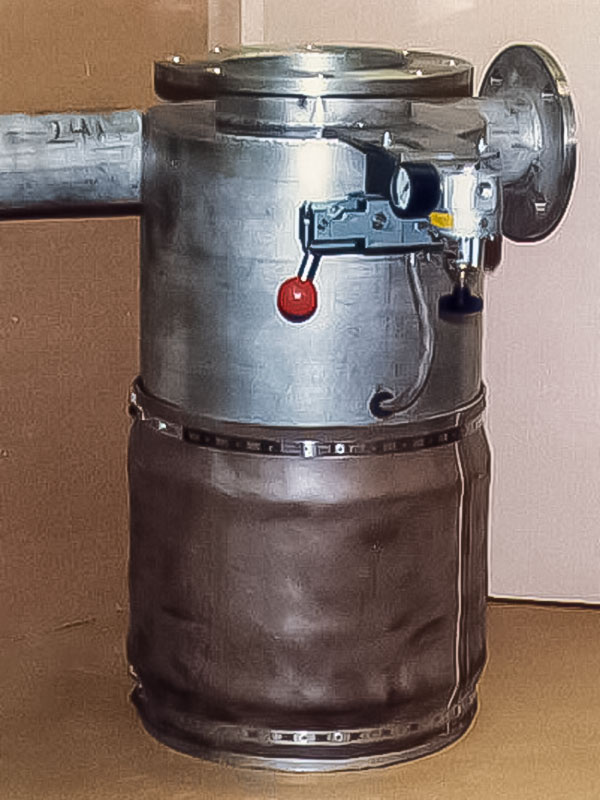

DRUM FILLING STATION

Dust-free drum filling stations are available in a variety of sizes.

BAG FILLING STATION

DCL bag filling stations can handle bags from 25 to 60 cubic square feet.

ROTARY BAG FILLING STATION

Rotary Bag filling stations are available in a variety of sizes.

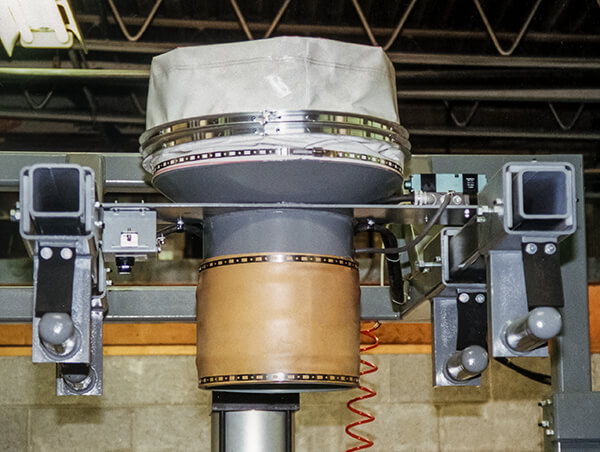

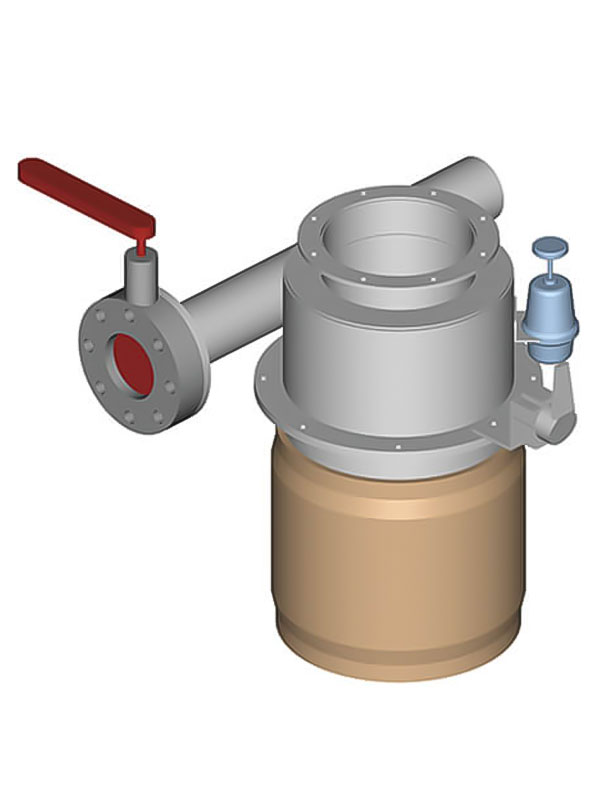

BAG FILLING NECK

Bag all types of products – fine, granular, lumpy, abrasive, corrosive, dusty or sanitary applications.

DRUM FILLING STATION

DCL’s dust-free drum filling stations are available in a variety of sizes to meet your specific need.

Our experienced engineers can design the perfect system to suit your application.

Application Data Sheets

Product Literature

Specifications

DCL’s Drum Filling systems use high-accuracy scales with manual sequence or PLC controls. A wide variety of options allow for manual or fully automatic operation.

Options include:

- automatic drum centering

- X-Y axis tables to allow filling of four drums on a pallet

- powered and gravity roller conveyors

- empty drum staging equipment

- full and dribble feed product flow control valve

- box filling adapters

- simultaneous weighing and densifying

A choice of construction materials allows you to effectively bag all types of products – fine, granular, lumpy, abrasive and corrosive – and difficult dusty or sanitary applications. You can also choose from the electrical options that are best suited for your environment: NEMA 4, NEMA 4X, NEMA 7, NEMA 9, 120V/220V control, 460V/415V power, etc.

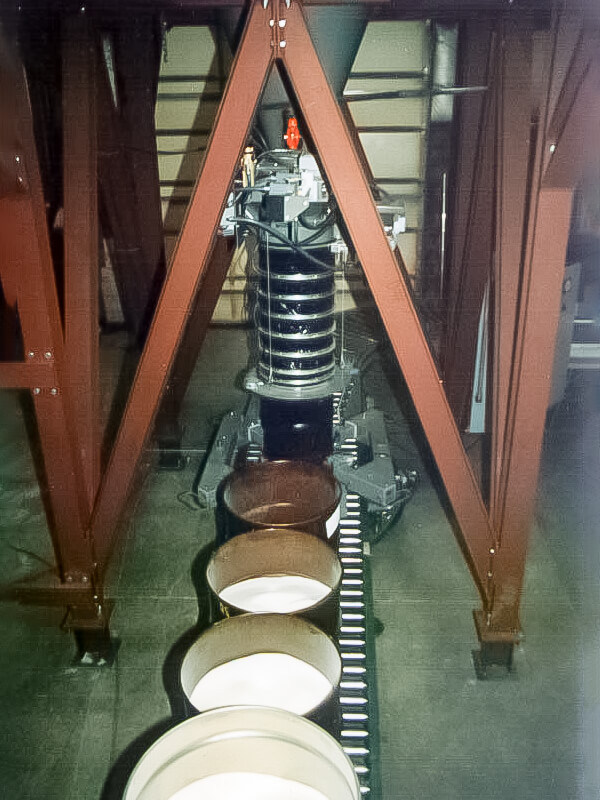

ROTARY BAGFILL STATION

Achieve up to 50 bags an hour with DCL’s Rotary Bagfill System.

DCL’s dust-free Rotary Bag filling stations are available in a variety of sizes to meet your specific need.

Our experienced engineers can design the perfect system to suit your application.

Application Data Sheets

Product Literature

Specifications

DCL’s Rotary Bagfill Station consists of a weigh-bin above a retractable fill tube that seats into the fill neck on a rotating turret, providing an operator’s side with a platform to load empty bulk bags, and a load side, that loads the bag with the pre-measured material from the weigh-bin. Once the weigh-bin gate opens, the vibrating grid simultaneously densifies the material to stabilize the load, reducing cycle times. Once the bag is filled, the gate on the weigh bin closes, the neck seal deflates, hooks release, and the powered roller conveyor takes the bag away to be unloaded. While the bulk bag on the load side is being filled, the operator is installing an empty bulk bag on the operator’s side. When the filled bulk bag is conveyed and clear of the turret, the empty bag is rotated to the load side, the weigh-bin is refilled and the cycle begins again. The turret height can be adjusted to accommodate different-sized bags.

A choice of construction materials allows you to effectively bag all types of products – fine, granular, lumpy, abrasive and corrosive – and difficult dusty or sanitary applications. You can also choose from the electrical options that are best suited for your environment: NEMA 4, NEMA 4X, NEMA 7, NEMA 9, 120V/220V control, 460V/415V power, etc.

BAG FILLING STATION

DCL offers a wide variety of bag fill stations that can handle bags from 25 to 60 cubic square feet.

Application Data Sheets

Product Literature

Specifications

DCL’s dust-free bulk bag filling stations are provided in configurations tailored for your specific bagging application. They can be designed to accommodate a full range of bag sizes. The systems use high-accuracy scales with manual sequence or PLC controls. The bag fill station comes in two typical designs, a two-post, and four-post.

A wide variety of options offer you manual or fully automatic operation. Bag filling options include:

- automatic strap release

- powered and gravity

- roller conveyors

- empty pallet dispenser

- full and dribble feed product flow control valve

- drum and box filling adapters with

- simultaneous weighing and densifying and integral filters

A choice of construction materials allows you to effectively bag all types of products – fine, granular, lumpy, abrasive, and corrosive – and difficult dusty or sanitary applications. You can also choose from the electrical options that are best suited for your environment: NEMA 4, NEMA 4X, NEMA 7, NEMA 9, 120V/220V control, 460V/415V power, etc.

BAG FILLING NECK

Product Literature

Specifications

Bag filling necks are typically used in conjunction with a bag filling station. Once the bag is placed on the filling neck, a bladder is inflated, allowing for a complete, dust-tight seal. The bag filling neck dust outlet must be ducted to a dust collector to pull the air and dust from the bag.

A choice of construction materials allows you to effectively bag all types of products – fine, granular, lumpy, abrasive, and corrosive – and difficult dusty or sanitary applications. You can also choose from the electrical options that are best suited for your environment: NEMA 4, NEMA 4X, NEMA 7, NEMA 9, 120V/220V control, 460V/415V power, etc.

DUST CONTROL & LOADING SYSTEMS

The industry leader in dust control

and dry bulk loading systems since 1981.

© 2023 Dust Control and Loading Systems

Website by Brick House Interactive